1. Limanete tsa neodymium hangata li entsoe ka motsoako o phofshoana oa neodymium, tšepe, le boron o siling hammoho tlas'a mocheso o phahameng le khatello ea ho etsa sehlahisoa se felileng.

2. Motsoako oa phofo o kenngoa ka har'a hlobo kapa setshelo ebe o futhumatsoa mocheso o phahameng e le hore o qale ho qhibiliha le ho fuse.

3. Hang ha thepa e fihla sebakeng sa eona sa ho qhibiliha, e tšoaroa ka mocheso ona ka nako e itseng ho fihlela e tiisa sekoahelo se le seng ho se na likheo kapa ho phunyeha pakeng tsa likaroloana.

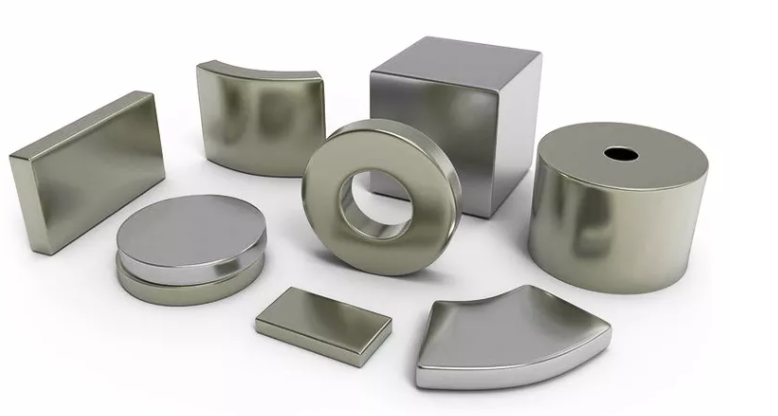

4. Ka mor'a hore ho be le ho tiisa ho etsahala, makenete e ka kenngoa ka sebōpeho le boholo ba eona bo lakatsehang ho sebelisa lisebelisoa tse sa tšoaneng tsa ho itšeha tse kang mechine ea ho sila kapa lathes ho itšetlehile ka litlhaloso tsa kopo.

5. Mathōko a makenete a ka belisoa ka boreleli haeba a ratoa pele a apesoa ka lintho tse sireletsang joalo ka nickel kapa zinki molemong oa ho thibela ho bola.

Lintlha tse ling mabapi le ts'ebetso, ka kopo bona chate e ka tlase:

| Che. | Phallo ea Ts'ebetso | Mohato oa Tlhahiso | Ts'ebetso ea Theknoloji |

| 1 | Tlhahlobo ea Raw Material | 1.ICP-2.chemical Analysis-3.Analyser(C&S) | Ho fumanoa ha Rohs Tlhahlobo ea Sebopeho Bohloeki Analysis |

| 2 | Kalafo ea Raw Material esale pele | 4.Sawing- 5. Drying- 6.Impact Cleaning | Tshipi ya Sawing Ho Omisa Moea o Chesang Tlhoekiso ea Tšusumetso |

| 3 | Taolo ea metsoako | 7.Taolo ea metsoako | Bela Batching Kopanya Raw Material |

| 4 | Strip Casting | 8.Vacuumizing-9.Melting-10.Casting | Ho hloekisa Ho qhibiliha Ho qhibilihisa Ho lahla |

| 5 | Ho fokotseha ha haerojene | 11.Pele ho phekolo-12.Vacuumizing-13.Eketsa Hydrogen | Ho phekola pele Ho hloekisa Senya ka Hydrogen |

| 6 | Milling | 14.Shattering-15.Grinding-16.Jet Mill-17.Granularity Control | Ho pshatla Ho sila Jet Mill Tekanyo ea Rogular |

| 7 | Ho hatella | 18. Boima ba phofo -19.Ho hatella pele - 20.Ho hatella -21. Isostatic tobetsa | Boima ba phofo Tobetsa pele Ho hatella Isostatic tobetsa |

| 8 | Sintering | 22.Vacuumizing- 23.Sintering -24 Phekolo ea mocheso | Ho hloekisa Sintering Phekolo ea mocheso |

| 9 | Tlhahlobo | 25.BH mothinya-26. PCT-27. Teko ea letsoalo -28.Roughcast Inspection | Tekanyo ea makenete Teko ea coefficient ea mocheso PCT Tekanyo ea Tekanyo Tlhahlobo |

| 10 | Mochini | 29.Ho sila -30.Ho seha mohala-31.Ho seha lehare ka hare | Ho sila Ho poma ka terata Ho poma lehare ka hare |

| 11 | Tlhahlobo ea mohlala ea QC | 32.QC tlhahlobo ea mohlala | Tlhahlobo ea mohlala ea QC |

| 12 | Chamfering | 33. Ho kgahla | Chamfering |

| 13 | Electroplating | 34. Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Chemical Ni | Electroplating Zn Motlakase oa NICUNI Phosphating kapa Chemical Ni |

| 14 | Tlhahlobo ea ho roala | 38.Botenya-39.Corrosion Resistance -40. Adhesiveness-41.-Tlhahiso ea Mamello | Botenya Khanyetso ea Corrosion Ho khomarela Tlhahlobo ea Mamello |

| 15 | Magnetization | 42.Tlhahlobo e Feletseng- 43.Tshwaya- 44.Arraying/Involution- 45.Magnetizing | Tlhahlobo e Feletseng Ho tshwaya Ho hlopha/ Ho itlhahisa Magnetizing Tlhahlobo ea Magnetic Fiux |

| 16 | Ho paka | 46. Magnetic Flux- 47.Bagging- 48. Ho paka | Ho kenya mokotla Ho paka |

Nako ea poso: Feb-15-2023